The Pros and Cons of 3D Printed Prosthetics

Introduction

In recent years, 3D printing technology has revolutionized the field of prosthetics, offering innovative solutions for individuals in need of limb replacements. With the ability to create customized prosthetic devices, 3D printing has gained significant attention and popularity. In this blog post, we will explore the pros and cons of 3D printed prosthetics, examining their potential benefits as well as the challenges they may present. Let’s dive in!

Pros of 3D Printed Prosthetics:

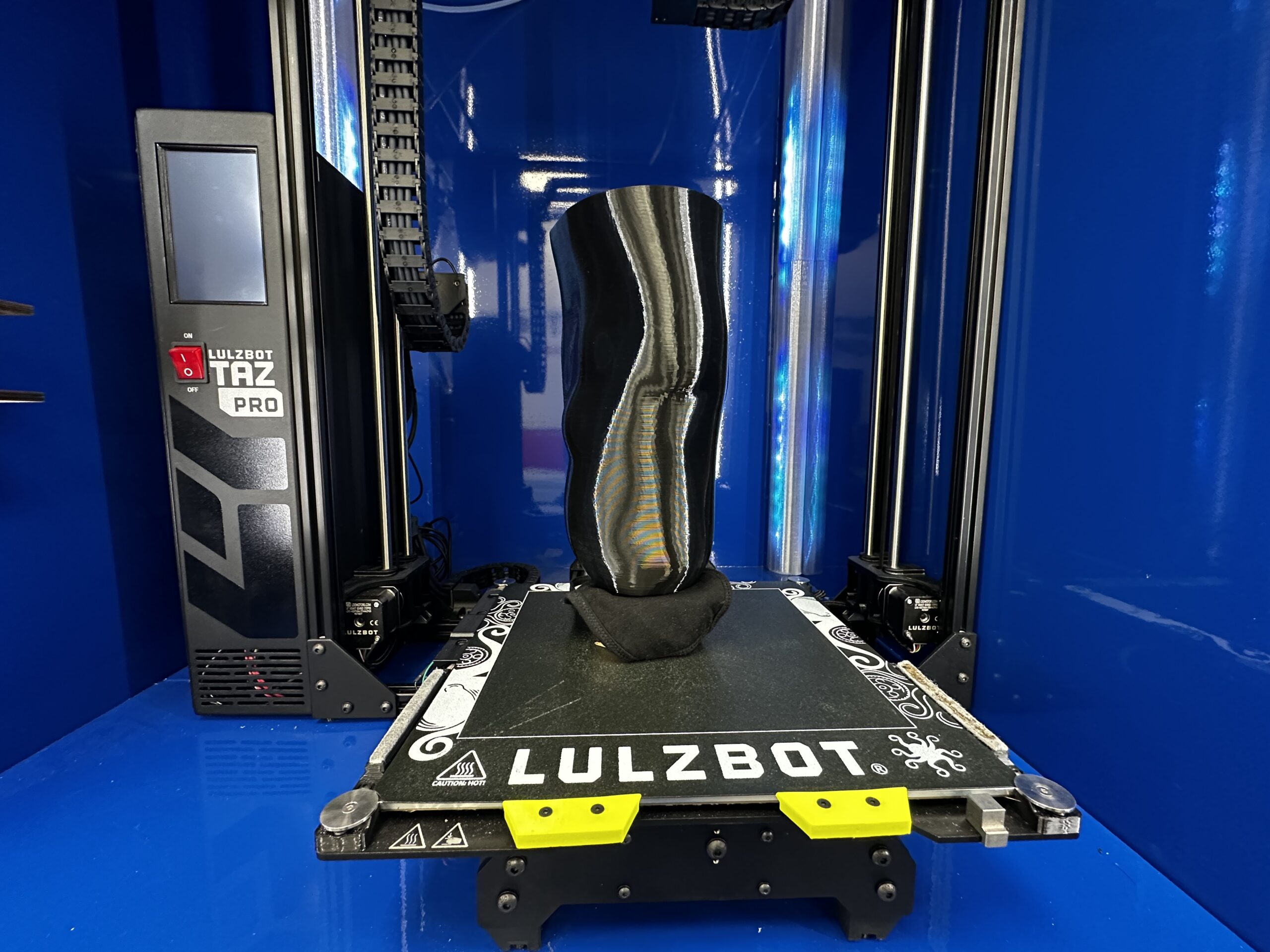

- Customization and Personalization: One of the significant advantages of 3D printed prosthetics is their ability to be customized to meet the unique needs of individual patients. With 3D scanning and modeling techniques, prosthetists can create personalized devices that perfectly fit the patient’s residual limb, ensuring optimal comfort and functionality.

- Cost-Effective Production: Compared to traditional manufacturing methods, 3D printing can significantly reduce production costs for prosthetic devices. The ability to create prosthetics using less material and streamlined manufacturing processes makes 3D printed prosthetics more accessible and affordable for patients.

- Rapid Prototyping and Iteration: 3D printing allows for rapid prototyping, enabling prosthetists to quickly iterate and refine the design of the prosthetic device. This iterative process helps optimize the fit, comfort, and performance of the prosthetic, ensuring that patients receive the best possible outcome.

- Lightweight and Comfortable: Prosthetic devices created through 3D printing can be lightweight and comfortable to wear. The use of lightweight materials and the ability to customize the fit results in prosthetics that are less burdensome on the residual limb, enhancing overall comfort and reducing fatigue.

Cons of 3D Printed Prosthetics:

- Durability and Longevity: One of the challenges with 3D printed prosthetics is ensuring their durability and longevity. Depending on the materials used and the design complexity, 3D printed prosthetics may not always have the same level of durability as traditionally manufactured prosthetics. Further research and development are necessary to improve the longevity of 3D printed prosthetic devices.

- Limited Material Selection: While 3D printing offers versatility in design, the range of materials available for prosthetic fabrication may be limited. Traditional prosthetic materials, such as carbon fiber, may not be compatible with current 3D printing technologies, which can impact the strength and performance of the final product.

- Skill and Expertise Requirements: Implementing 3D printing in prosthetic production requires specialized knowledge and expertise. Prosthetists and healthcare professionals need to acquire the necessary skills and training to utilize 3D printing effectively. Additionally, ongoing research and development are essential to stay updated with the latest advancements in 3D printing technology.

Conclusion: 3D printed prosthetics have the potential to revolutionize the field of prosthetics, offering customization, cost-effectiveness, rapid prototyping, and lightweight designs. While there are challenges to overcome, such as durability and material selection limitations, the continuous advancements in 3D printing technology are promising. By combining the strengths of 3D printing with the expertise of prosthetists, we can create prosthetic devices that truly enhance the lives of individuals in need.

Note: It is crucial to consult with healthcare professionals and prosthetists to determine the most suitable prosthetic options based on individual needs and considerations.

OPENING HOURS

| Mon – Fri | 8:00 – 4:30 |

| Saturday | CLOSED |

| Sunday | CLOSED |